THE CRFQ PROJECT

The CRFQ project is an initiative that aims to produce comprehensive mapping and physical-chemical characterization of fermentable residues in Quebec. To date, 25 companies have collaborated on the project, and more than 80 samples from these partners have been analyzed and characterized. The results of this project will be made available to the MAPAQ, the research community (universities, CEGEPs, research centers, etc.), municipalities, and industries in Quebec interested in industrial biotechnologies involving fermentation and the circular economy.

In a sustainable development concept, the circular economy consists of preserving existing natural resources and transforming waste into useful products. This economic model aims to minimize resource consumption and disposal and extend the life of products and by-products. To achieve this, it is necessary not only to develop innovative technologies, but also to have access to residual materials that can be recovered. In the field of industrial biotechnology, there has been much progress, especially in industrial bioprocesses related to fermentation. In Quebec, despite these advances in research and innovation, industrial applications are still underdeveloped. One reason for this is the lack of data on opportunities for the efficient and profitable use of fermentable residues. It is therefore essential to compile an inventory of these residues in terms of their availability in Quebec and to analyze their physical and chemical composition in order to fully understand their fermentable potential. In a sustainable development concept, the circular economy consists of preserving existing natural resources and transforming waste into useful products. This economic model aims to minimize resource consumption and disposal and extend the life of products and by-products. To achieve this, it is necessary not only to develop innovative technologies, but also to have access to residual materials that can be recovered. In the field of industrial biotechnology, there has been much progress, especially in industrial bioprocesses related to fermentation. In Quebec, despite these advances in research and innovation, industrial applications are still underdeveloped. One reason for this is the lack of data on opportunities for the efficient and profitable use of fermentable residues. It is therefore essential to compile an inventory of these residues in terms of their availability in Quebec and to analyze their physical and chemical composition in order to fully understand their fermentable potential.

This initiative will help forge synergies and various models of collaboration between industrial partners and research communities, and develop a promising industrial sector that uses advances in biotechnology to recover residual materials that are currently disposed of without regard to their potential value, disposal cost, or environmental impact.

Fermentable residues have underestimated potential. They are largely underutilized despite representing a significant source of raw materials for the production of a wide range of high value-added products. In Quebec, tens of thousands of tons of fermentable waste materials are produced by businesses and underutilized every year. However, these materials can be recovered through innovative biotechnological processes to produce bioplastics, biofertilizers, industrial bioproducts, and molecules of interest to the pharmaceutical and cosmetics sectors. By promoting their local processing, Quebec could not only reduce its environmental footprint, but also stimulate the circular economy and support the development of a sustainable and competitive bioeconomy.

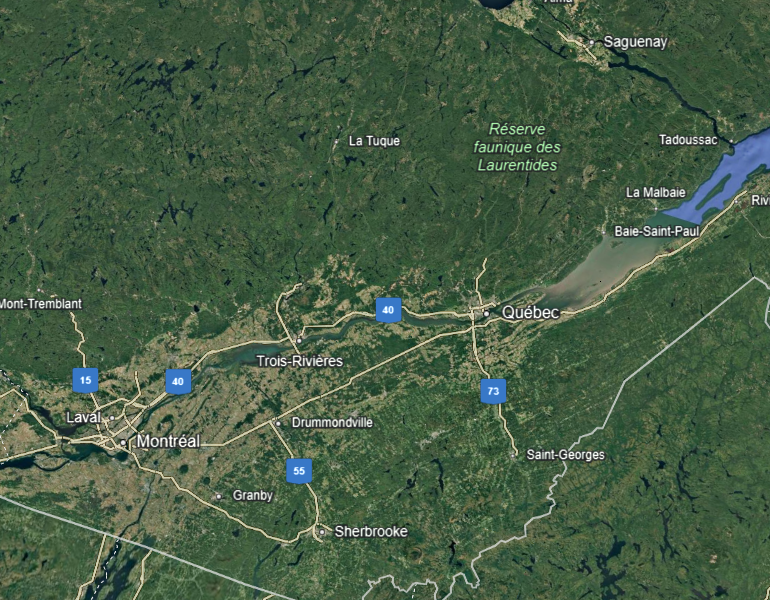

INTERACTIVE MAP

Explore fermentable residues in Quebec province using the interactive map. The markers on the map indicate the location and name of the companies that produce these residues. Clicking on a marker displays a window with a description of the company and the physical and chemical characteristics of the fermentable residues it generates. Only companies that have given their consent to the dissemination of their data appear on the interactive map. The theme panel at the bottom right provides thematic exploration, while full-screen mode can be activated by clicking on the square at the top right of the map. This map will evolve regularly with the addition of new companies wishing to submit their residues for analysis and characterization, with a view to proposing potential recovery options.

A few avenues

of possible valorization

| Input examples | Fermentation process | Process description | Bioproducts |

|---|---|---|---|

| Industrial effluents (secondary paper mill sludge, cheese by-products, starch wastewater, used cooking oils, etc.) | Aerobic fermentation | Production of polyhydroxyalkanoates (PHA) through microbial fermentation | Biopolymers |

| Production of spores and toxins (e.g., Bacillus thuringiensis) for pest control | Biopesticides | ||

| Production of industrial enzymes (protease, amylase, lipase) and biosurfactants (surfactin, iturin, etc.) | Bio-detergents | ||

| Production of secondary metabolites to enhance soil and plant health | Biofertilizers | ||

| Formulation, production d’enzymes et surfactants pour la dégradation des hydrocarbures | Bioremediation | ||

| Production de lipides microbiens (SCO) pour biodiesel ou oméga-7 | Biodiesel | ||

| Agri-food effluents (whey permeate, buttermilk, etc.) | Aerobic fermentation | Production of natural colors and flavors, production of galacto-oligosaccharides, Production of natural colors and flavors, production of galacto-oligosaccharides, | Flavors, Functional fibers, Prebiotics, and Postbiotics |

| Industrial solid waste (citrus peel, apple pomace, hydrosols, limonene, carvacrol, menthol, etc.) | Aerobic fermentation | Transformation of molecules (e.g., terpenes) into bioactive or value-added compounds | Bioactive compounds (active packaging, essential oils, antimicrobial or insect repellents) |

| Green extraction | Extraction of essential oils or volatile compounds by distillation or sonication | Essential oils | |

| Lignocellulosic residues (corn, alfalfa, cranberry residues, etc.) | Aerobic/anaerobic fermentation | Production of industrial enzymes (cellulase, xylanase, laccase) for enzymatic hydrolysis and release of fermentable sugars | Lignocellulosic enzymes, bioethanol |

Services

Technical services

We offer industrial process scaling services to our customers while maintaining the desired product quality and safety.

We work closely with them to design tailored, cost-effective solutions. The technical services we offer include:

- The treatment of residual waste and the improvement of its biodegradability;

- Isolation of wild strains from putrescible residues;

- Production of microbial and fungal biopesticides, microbial inoculants, industrial enzymes, bioplastics, and biohydrogen;

- Study of aerobic or anaerobic fermentation parameters (culture media, strains, microorganisms, growth conditions);

- Optimization of bioprocesses (experimental planning, statistical data processing, fed-batch culture, etc.);

- Scaling up of bioprocesses to 2000 L;

- Concentration or recovery of microbial products on a semi-industrial scale by centrifugation (continuous or semi-continuous), microfiltration, and ultrafiltration;

- Semi-industrial scale formulation of recovered microbial products in granule or powder form;

- Semi-industrial scale purification of microbial products by ion exchange chromatography or freeze-drying;

- Conducting feasibility studies and technical-economic studies;

- and many other services.

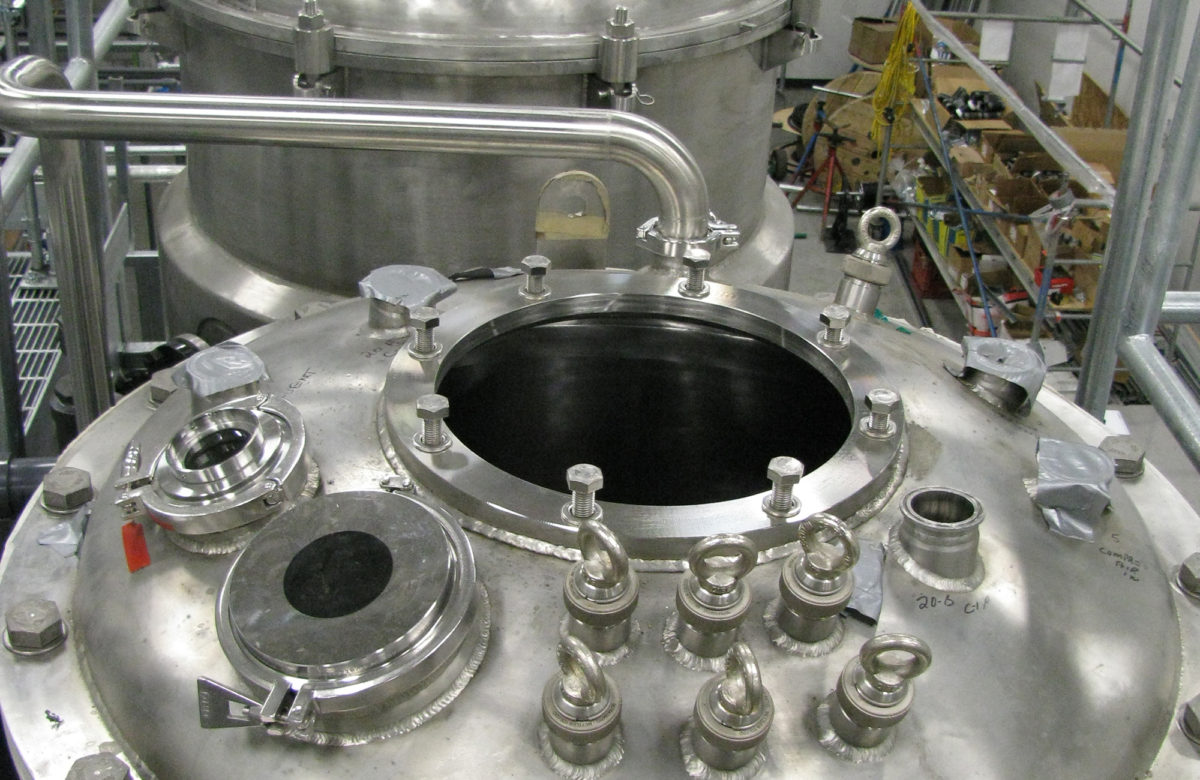

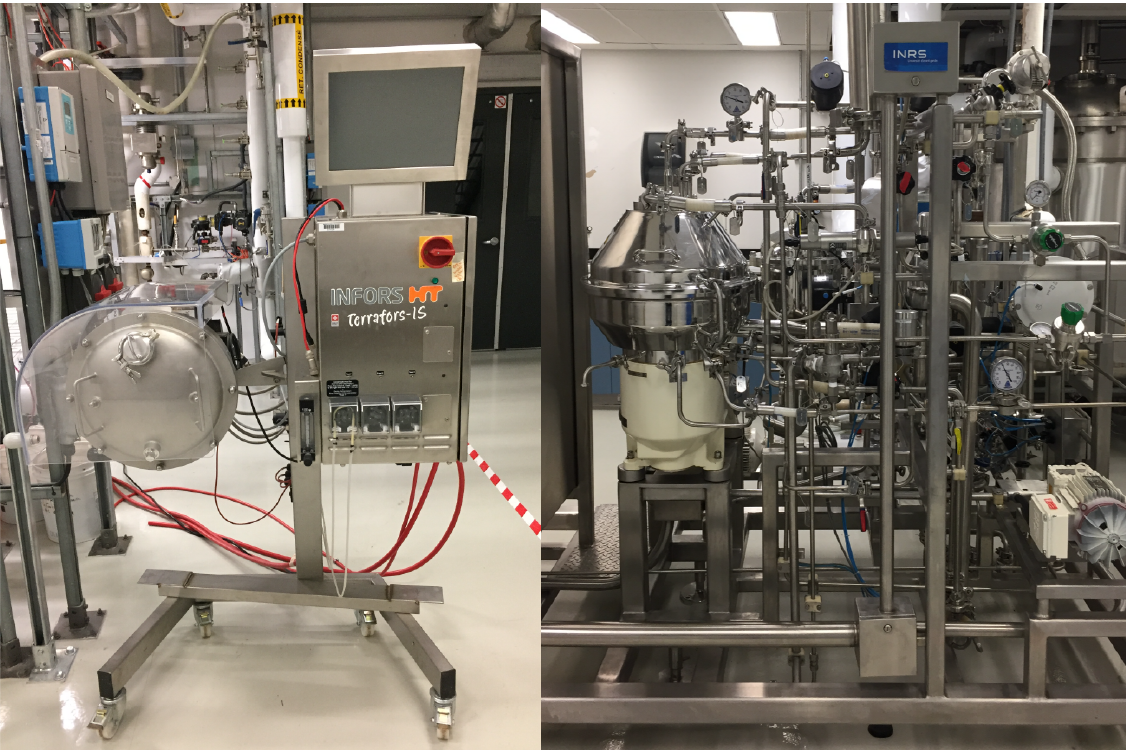

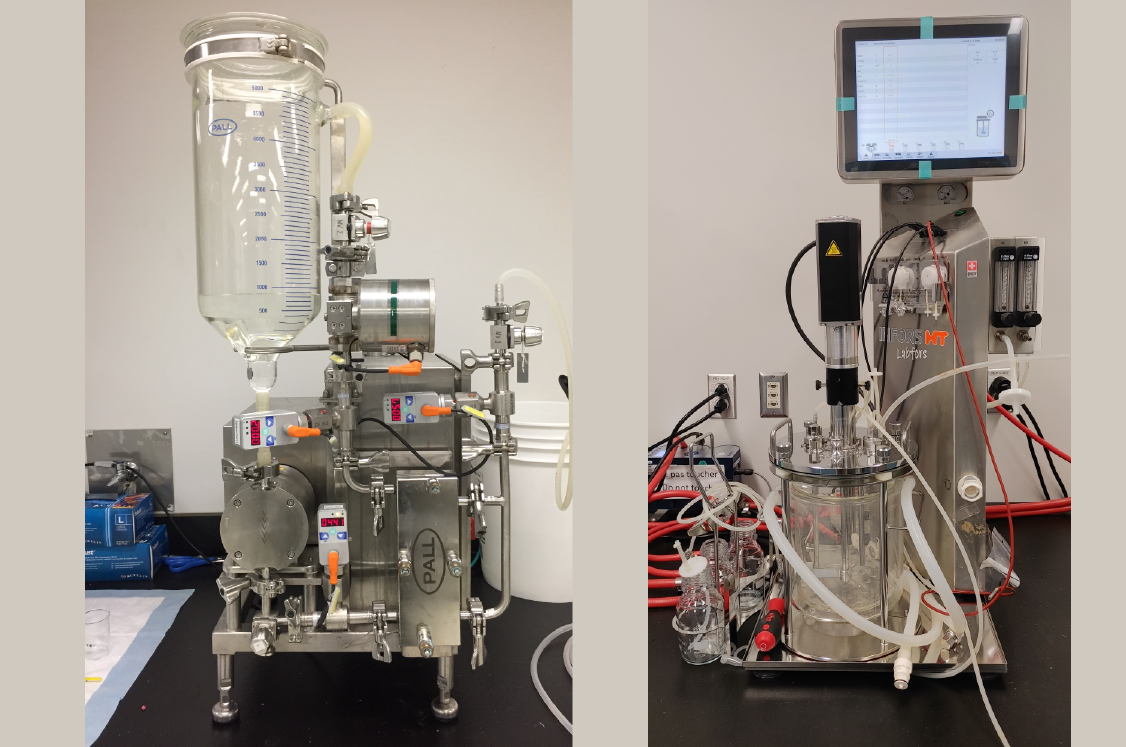

Facilities

We offer our customers access to facilities to meet their production needs. We have a wide range of state-of-the-art facilities available to our customers to meet all their specific requirements. Our facilities include, among others:

Nous disposons d’un large éventail d’installations de pointe, que nous mettons à la disposition de nos clients pour répondre à toutes les exigences spécifiques de nos clients. Nos installations comprennent entres autres:

- Two fermentation laboratories (biosafety level 1) reserved for the use of unconventional substrates and conventional substrates equipped with a series of bioreactors (2 x 5 L, 2 x 15 L, 2 x 150 L, 1 x 2000 L);Two fermentation laboratories (biosafety level 1) reserved for the use of unconventional substrates and conventional substrates equipped with a series of bioreactors (2 x 5 L, 2 x 15 L, 2 x 150 L, 1 x 2000 L);

- Equipment for the upstream processing of unconventional fermentation substrates, including an industrial sieve and two hydrolysers (150 and 2000 L – the latter can also be used as a 2000 L bioreactor);

- Equipment for semi-industrial-scale downstream processing of fermented broths, including an industrial disc centrifuge, a microfiltration and ultrafiltration system, a spray dryer, an ion exchange chromatography system, and a freeze dryer

- An environmental chamber (biosafety level 2) for inoculum production and strain storage, as well as quality control and characterization of purified microbial products;

- An analytical laboratory for the characterization of unconventional substrates, quality control of certain microbial products, and process monitoring, equipped with GC-MS, LC-MS-MS, and a flow cytometer, among other instruments.

- And many other state-of-the-art pieces of equipment.

Equipment

and facilities

OUR PARTNERS

We are proud to work with trusted partners who share our vision and values. Together, we strive to deliver innovative solutions. We are also grateful to our partners for their commitment and continued trust.

A note from the principal investigator

"I would like to express my gratitude to the"I would like to express my gratitude to Fondation de l’INRS and its donors, particularly RBC and Stantecfor their financial support for this project on the inventory, management, and recovery of fermentable organic waste in Quebec. I would also like to thank the team membersthe project coordinator, the website developer, the co-researchers, collaborators, etc., for their commitment and valuable contributions throughout this initiative. Finally, I would like to thankthe project coordinator, the website developer, the co-researchers, collaborators, etc., for their commitment and valuable contributions throughout this initiative. Finally, I would like to thank M. Claude Bourget, Mme Carole Parent and M. Jean-Philippe Chenelfor their unwavering support at the beginning of this project.

Prof. Kokou Adjallé

Team member

Prof. Kokou Adjallé

Project Manager

Prof. Denis Groleau

Collaborator / Consultant

Dr. Adama Ndao

Project Coordinator

Dr. Delon Konan

Website developer

Geneviève Rioux

Collaborator

Prof. Éric Déziel

Co-investigator

Prof. Philippe Constant

Co-investigator

Prof. Tarek Rouissi

Co-investigator

Prof. Eric Peterson

Co-investigator

Dr. Mathieu Drouin

Collaborator / Consultant

Prof. Simon Barnabé

Collaborator

Prof. Grant Vandenberg

Collaborator

Mapping of fermentable residual matter in Quebec

Plan

Our Services

- Consulting

- Scaling up

- Environmental bioengineering

- Process development

- Waste valorization

Our Services

- Adresse : 2605, boulevard du parc technologique, Québec (Québec), Canada.

-

Tel : +1 (418) 654 2610

- Email : kokou.adjalle@inrs.ca

© All rights reserved